Hi friends,I'am AIT-LASRI YOUNES

In this project we will talk about making corrupted DVD and cd-rom drives recycled and producing cnc at low cost. Let's start building the mini cnc project that draws

Step 1: Materials

- Arduino (can be nano, uno or mega)

- Damaged DVD or CD-ROM (the stepper motor inside will be running)

- 2 pieces of damaged dvd or cd-rom (the stepper motor inside will be running)

- Servo motor (Mg90 is enough)5v 2

- amp battery or adapter

- Plexi plate with 20 x 16 cm and 5 mm thickness to hold the X axis.

- Plexi plate 15 x 16 cm and thickness 5 mm to secure the Y axis

- You can use a plexi plate of 75 × 75 mm and a thickness of 5 mm for the drawing surface.

- 1 piece M5 bolt nut (to fix the plate)

- 14 pieces M4 bolt nut

Step 2: Front and rear overview of the mini cnc and explanations

- X plane Plexi Plate (200x150x3 mm)

- Y plane Plexi Plate (200x150x3 mm)

- X-axis movement mechanism (dvd drive yard mechanism)

- Y-axis movement mechanism (dvd drive yard mechanism)

- Z plane section

- Servo-motor

- Pen Holder

- Pen fixing nut - screw arrangement (1 piece M5 bolt nut)

- Pen

- Drawing table (75x75x5 mm plexi plate)

- Axis supports and screw nuts

- Stepping motor for X-axis motion

- Stepping motor for Y-axis movement

- Paper clips to secure the paper

- 14 pieces M4 bolt nut

- Pen holder support

- Z-axis

- Cables4

- Angles

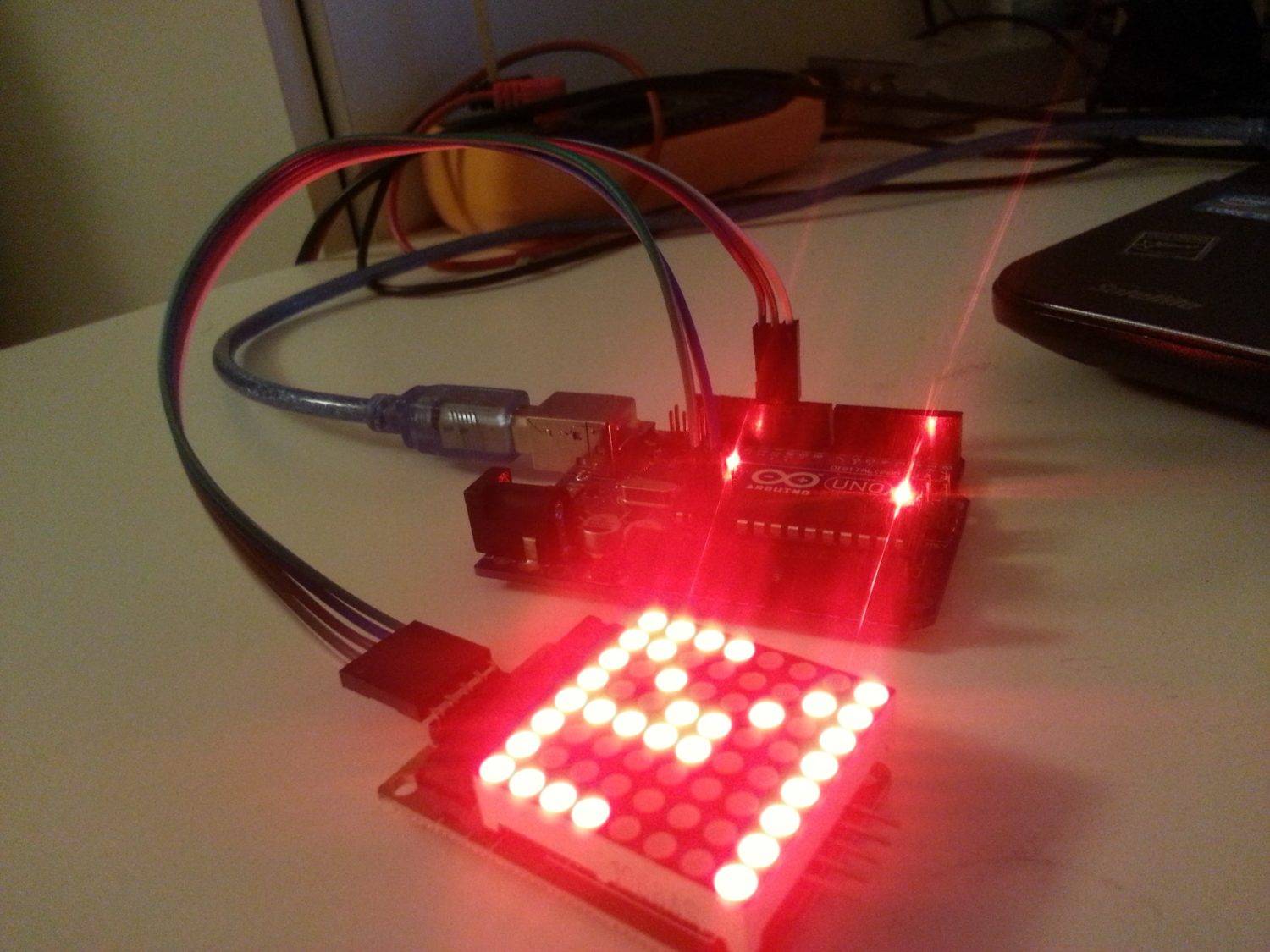

- The control unit (Arduino uno, 2 l239d, pertinaks, energy input jack)

- Usb cable for computer connection

Step 3: Mechanical part

We will use the part with the mechanical part DVD or the rail system inside the Cd-R0m drive.In this section the stepper motor is connected to the worm screw shaft and moves the part of the laser reader which is connected to the shaft by turning the shaft. We are removing this part without harm. In the same way, the other driver is also dismantled and a total of two stepper motor systems are installed. If you use DVD-Rom, you can also make laser cutter with its laser diodes. These are the mechanical parts that move the axes. We will extract other mechanical parts from the 3d printer.

You can download parts stl files here >>here (ici)

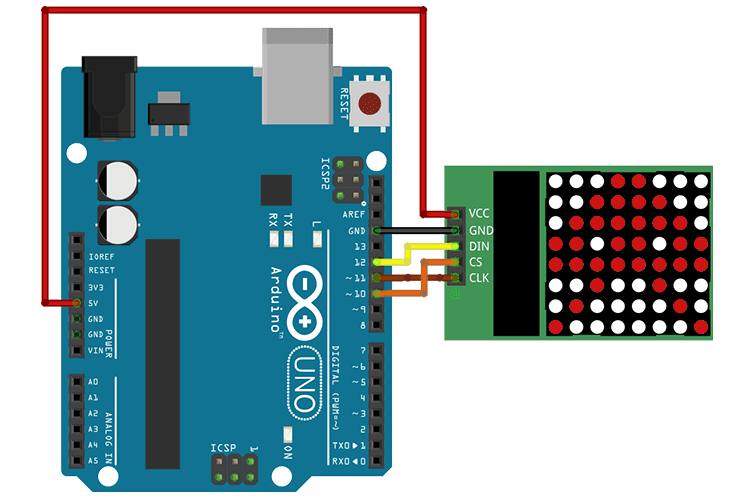

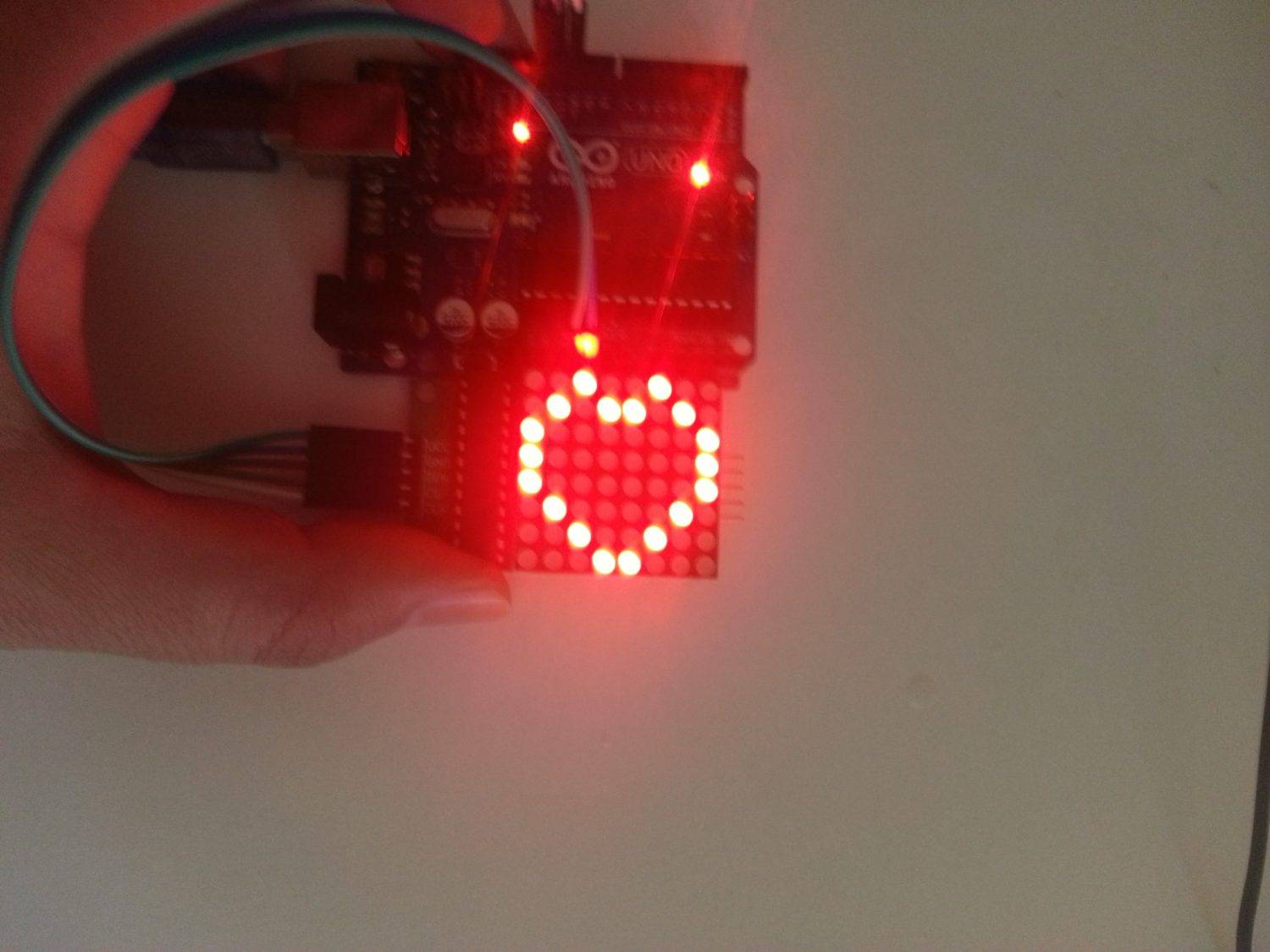

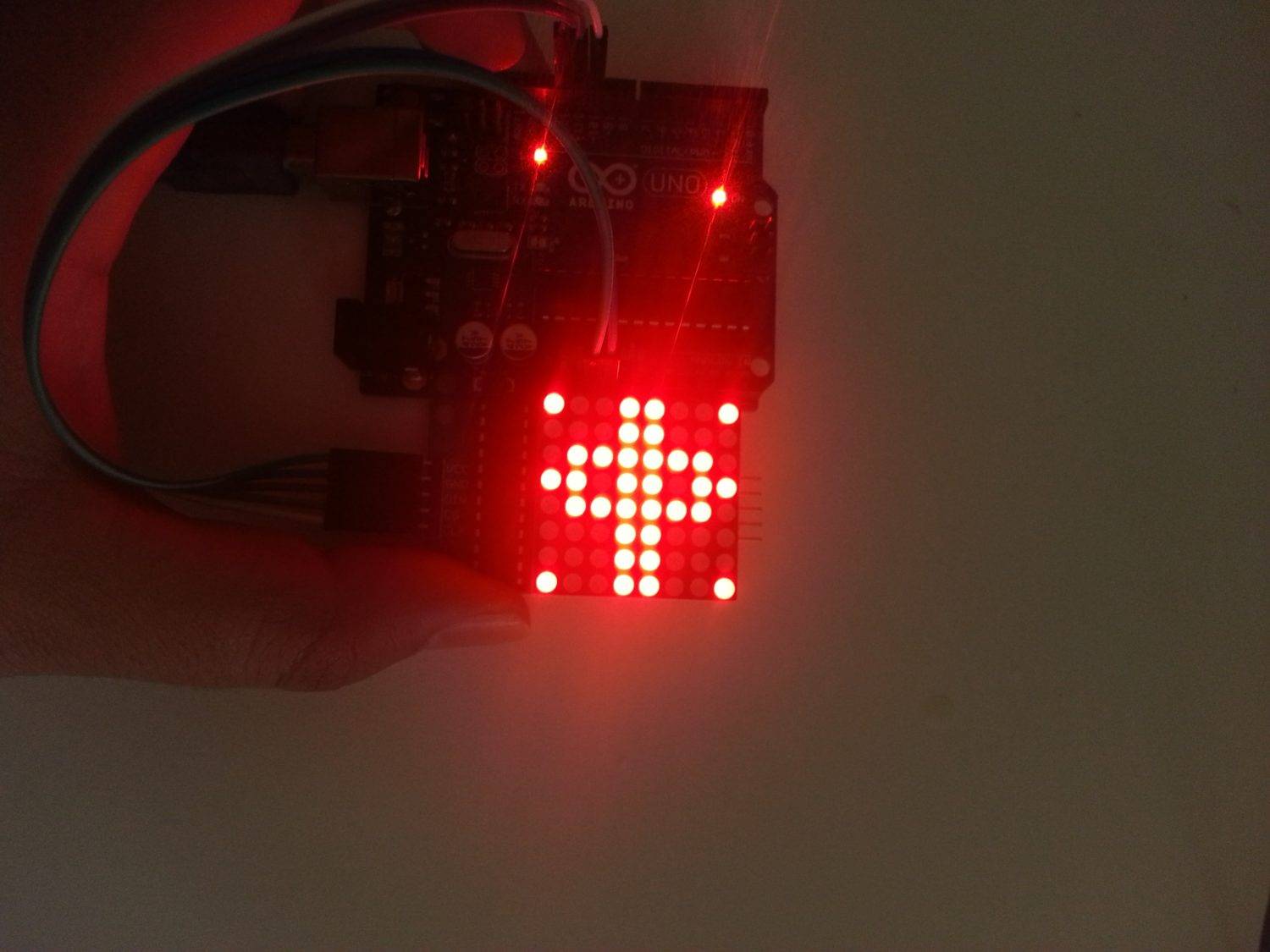

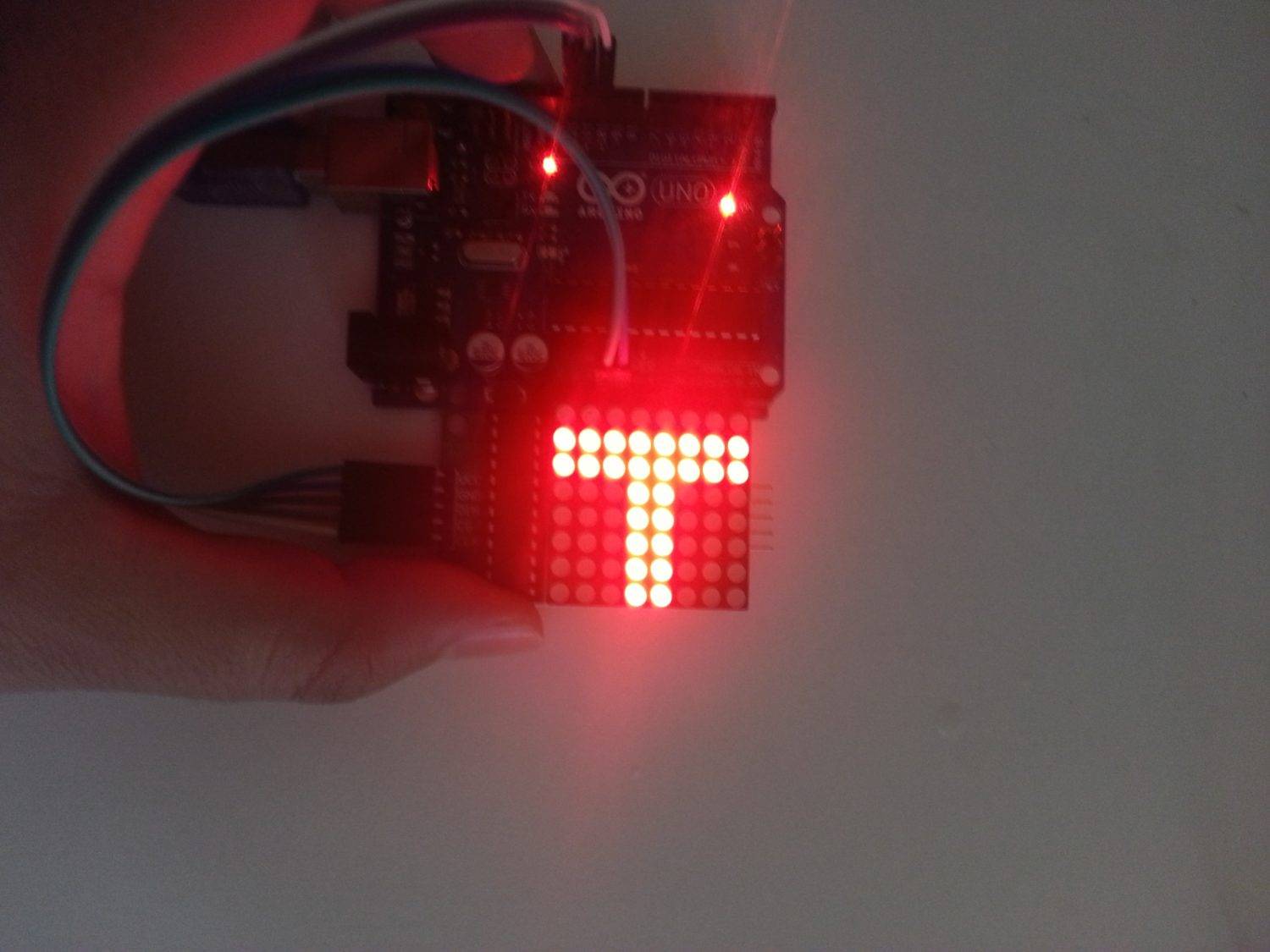

Step 4: Electronic Section

In our electronic system we will connect the two stepper motors which will move the x and y axis and one servo motor which will lift and lower the die.

Step 5: Arduino Code Part

download here : code.txt

Step 6: Processing Code

download here : code 2.txt

Step 7: INKSCAPE SETTINGS

To get gccode output with INKSCAPE, first download the makerbot unicorn G-code plugin here >> Inkscape gcode plugin

İnkscape full setting and details of the project >> Arduino cnc project

Step 7: INKSCAPE SETTINGS

To get gccode output with INKSCAPE, first download the makerbot unicorn G-code plugin here >> Inkscape gcode plugin

İnkscape full setting and details of the project >> Arduino cnc project